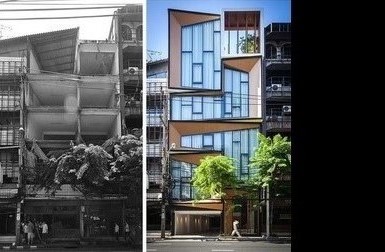

Prefabrication and Modular Construction

Modular Components maximize off-site construction speed while maintaining some design flexibility.

Practices to the table. We ensure clients receive experience-based modular construction means and methods expertise to assess the risks and drive the right decisions and solutions to achieve your objectives.

Modular Components ‘Kit of Parts’ Approach: Flexible and Familiar

Key building elements are prefabricated and then shipped to site to be sequenced into the building. The Kit of Parts may include: Precast core elements, stairs and elevator shafts, load bearing structural interior/exterior walls, interior non-bearing walls, prefabricated washrooms and mechanical/electrical rooms. The approach requires less up-front design work to release specific components to fabrication and uses readily available materials and construction methods well understood by trades.

Full Volumetric Approach: ‘Lego Block’ On-Site Assembly

Full volumetric modular is a process whereby large building modules are manufactured off site, then assembled on site like Lego blocks to create the structure and a near finished building. With the majority of ‘construction’ transferred to a facility, volumetric construction has the potential to reduce on site waste by 90% while the manufacturing and erection process produces less than 0.6% waste to landfill. Early integrated design modeling and resolution prior to module production is critical.

Design for Manufacture and Assembly (DfMA): An Engineering Methodology

DfMA works to accelerate production and reduce costs by ensuring both ease of manufacture of modular components as well as simplified assembly of those components into the final module, all during the early and iterative design phase of the project. Working with advance BIM technologies, our modular design experts and process engineers source cost-effective raw materials and work to Lean both the manufacturing and module assembly processes in order to reduce labor, time, costs and complexities.